If you only made one +Bow with the required materials then you have more than enough remaining plastic sheet to make an L+L. If you have made a +Bow already or you are planning to make a +Bow you will need to add the purchase the following items in order to make one L+L.

8585K43 - Polycarbonate Round Tube 1-1/2" OD, 1-3/8" ID, Clear = $3.48 for one Foot 4880K314 - Std-Wall (Schedule 40) White PVC Pipe Fitting 1" X 1/2" Sz, Pipe End Male X Socket Fem, Hex Bushing = $0.74 Each 92510A700 - Aluminum Unthreaded Round Spacer 1/2" OD, 1/8" Length, #6 Screw Size = $1.20 91780A131 - Aluminum Female Threaded Hex Standoff 1/4" Hex, 3/4" Length, 6-32 Screw Size = $0.44 Each (5) = $2.20 93505A111 - Aluminum Male-Female Threaded Hex Standoff 3/16" Hex, 1/4" Length, 6-32 Screw Size = $0.44 Each (4) = $1.76 90309A154 - Zinc-Plated Brass Unthreaded Round Spacer 3/8" OD, 1/4" Length, #6 Screw Size = $0.59 ea (2) = $1.18Total: $10.56

The rest of the parts are

9637K26 - Continuous-Length Compression Spring Spring-Tempered Steel, 11" L, .844" OD, .08" Wire - $10.12 per Pack of 5 90402A144 - Zinc-Plated Steel Pan Head Phil Machine Screw External Washer, 6-32 Thread, 1/4" Length = $5.36 per 100 90402A146 - Zinc-Plated Steel Pan Head Phil Machine Screw External Washer, 6-32 Thread, 3/8" Length = $5.31 per 100 90631A007 - Grade 2 Hex Nylon-Insert Locknut Zinc-Plated Steel, 6-32 Screw Sz, 5/16" W, 11/64" H = $2.02 per Pack of 100 (you only need two) 90272A159 - Zinc-Pltd Stl Pan Head Phillips Machine Screw 6-32 Thread, 2" Length = $5.71 per Pack of 100 (you only need one and you can also use a threaded rod) 90272A155 - Zinc-Pltd Stl Pan Head Phillips Machine Screw 6-32 Thread, 1-1/4" Length = $2.96 per pack of 100 (you only need two) 90272A151 - Zinc-Pltd Stl Pan Head Phillips Machine Screw 6-32 Thread, 3/4" Length = $2.96 per pack of 100 (you only need five)

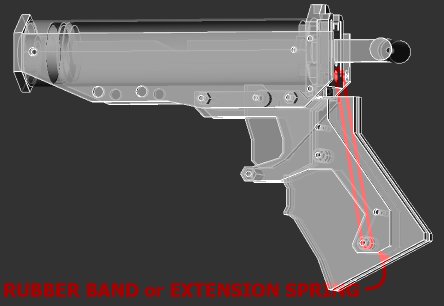

Instead of a compression spring the trigger plate is tensioned by a rubber band (doubled-up if needed) or extension spring of your choosing. This reduces the bulk on the top of the blaster.

Here's the SDK package

http://www.captainsl.../lplusl_sdk.zip (730kb)

which includes the partlist, .doc machining template sheet, Alibre Xpress .AD_PRT file, and the above image

Edited by CaptainSlug, 19 November 2008 - 04:49 AM.